Preservation of the Dynamometer is under way at the Illinois Railway Museum in Union, IL. If you would like to help with the preservation efforts, please contact us and come out for a day!

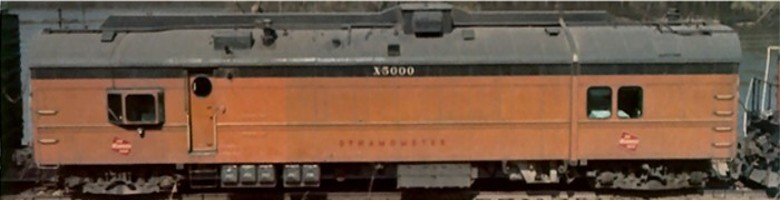

May 2010 – With the recent completion of Barn 11 the Dynamometer car X-5000 has been at least temporarily moved inside until the new MRHA Barn, is constructed. This is a much welcome development as it has been stored outside since leaving the Milwaukee Shops in 1987 and is in very desperate need of indoor storage. With this very encouraging development, there is now a need for volunteers for restoration.

desperate need of indoor storage. With this very encouraging development, there is now a need for volunteers for restoration.

To understand the scope of the restoration challenge, consider that relatively minor routine maintenance necessary to return the car to service required (from a documented dated 4/1/85) the use of the following skilled trades; carman, electrician, machinist, welder, refrigeration specialist, airman, pipefitter, trucksmith and plant and protection at the Milwaukee Shops with very extensive facilities. So initially, when the car was donated to IRM in 1992, the question was asked “how to go about sending it in for service? To which the answer was, “you don’t – you are it”, said Warren A. Newhauser, curator for the X-5000. “I vividly recall one day a few years ago looking at several places the roof had rusted through at the eaves from and realizing I had absolutely no idea how or where to begin” (state of mind was between restoration project phase II – disillusionment and phase III – panic!).  In addition, a huge learning curve also existed in order to simply set up to get work started at IRM. But through the help of many at IRM and elsewhere, by asking lots of questions, experimenting with new techniques, sometimes failing, excellent overall progress has been made over the past 3 years – mainly sealing up the metal roof. Some initial design flaws made by the Shops were discovered and corrected, such as layering two pieces of sheet metal on top of one another leading to trapped moisture and rust out.

In addition, a huge learning curve also existed in order to simply set up to get work started at IRM. But through the help of many at IRM and elsewhere, by asking lots of questions, experimenting with new techniques, sometimes failing, excellent overall progress has been made over the past 3 years – mainly sealing up the metal roof. Some initial design flaws made by the Shops were discovered and corrected, such as layering two pieces of sheet metal on top of one another leading to trapped moisture and rust out.  The repairs made now are all moisture proof and metal roof repair knowledge learned has even been shared for use with other projects! The next major initiative planned is sandblasting and painting the roof with the help a recent MRHA Emil Skok Preservation Grant received in Nov. 2009.

The repairs made now are all moisture proof and metal roof repair knowledge learned has even been shared for use with other projects! The next major initiative planned is sandblasting and painting the roof with the help a recent MRHA Emil Skok Preservation Grant received in Nov. 2009.