We had a productive work session on June 18, 2011 at IRM. Chuck Trabert and I checked for persistent roof leaks in three places.

There is one major leak through the A/C duct above the middle row of berths that we have been unable to find so far. Even using my iPhone as a video camera up into the duct, we were still unable to find the source of the water.

Chuck thinks he may have fixed it this time after spending a large part of the day on the roof.

There are a couple of very small leaks we marked with fluorescent orange paint (on 5/29/11 while it was raining in the middle of WWII battle reenactments) above the front closet and above the diesel fuel tank for the boiler.

I believe the section of the roof above the diesel tank will have to be replaced. It is probably about a two day job for 2 guys.

I believe the section of the roof above the diesel tank will have to be replaced. It is probably about a two day job for 2 guys.

Note: in each case the leak is no longer causing water damage to the car as we are collecting the water and it is a very small amount.

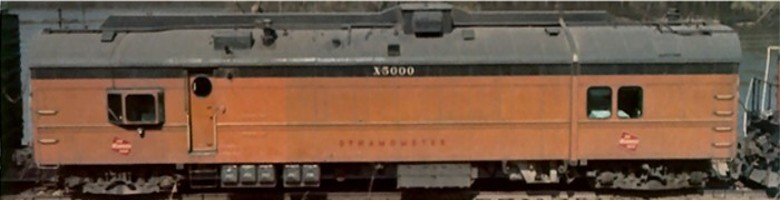

Meanwhile Larry Kuehn and Gary Olson scraped peeling paint from the sides and applied some phosphoric acid and metal prep to slow down the rusting since it will probably be a while before we paint the sides.

We also tried some standard methylene chloride paint remover from Home Depot to see how much work it was to remove the paint from the sides chemically.

We also tried some standard methylene chloride paint remover from Home Depot to see how much work it was to remove the paint from the sides chemically.

Turns out it is a LOT of work. A 2’x2′ square on the side took 20-30 mins with multiple applications of paint remover. In so doing we discovered the paint history of the car.

The coats of paint are: 1. brown primer, 2. black (with maroon band towards top of car), yellow primer, 3. orange, 4. orange.

Concluding that this paint remover was not a solution, I ordered and received a gallon of Spra Strip paint remover that is supposed to remove several layers of paint at a time (including Imron). We will try it next time out.

I also took back the 3 8V deep cycle golf car batteries and am charging them in my garage and will be testing to see if they are good enough to run the 32VDC electrical system. If these batteries I acquired are good enough, I will have to order one new one to make 32V. Sure would be nice to get the Enginator and electrical systems working this year!

I need to become a little more pro-active about scheduling work day at IRM to work on the X-5000 since there are more of us involved now. I admit I have been very last minute scheduling up to now but I need to be more proactive.

I need to become a little more pro-active about scheduling work day at IRM to work on the X-5000 since there are more of us involved now. I admit I have been very last minute scheduling up to now but I need to be more proactive.

Below are the weekend dates for July. If you are interested in working could you please let me know what date(s) work for you and hit Reply All and we will schedule it what works for everyone.

July 2/3

July 9/10

July 16/17

July 23/24

July 30/31

Dick Melzer is interested in joining us. His Dad worked on the Dyno before my Dad did and thus has a lot of history with the car. He was an electrician at the Shops and knows woodworking. We need all the help we can get in those areas. We all look forward to meeting you Dick!!

Warren Newhauser–